Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: +8613791936882 ,. Or call +86-18678911083 directly.

The durability and sturdiness of the flower cart depends on the quality of the main materials. The production usually requires the following key raw materials:

Before formal production, raw materials must undergo strict quality inspection to ensure that they meet the following requirements:

Metal sheets and tubes are cut into the required size and shape by laser cutting machine or CNC equipment. Common cutting parts include:

Using automatic welding robots or manual welding, the cut metal parts are welded and assembled into a large product frame or a pallet prototype. This is a key step that directly affects the load-bearing and stability of the cart.

Polish and grind the welded parts to remove welding burrs and sharp edges to ensure smoothness without sharp corners.

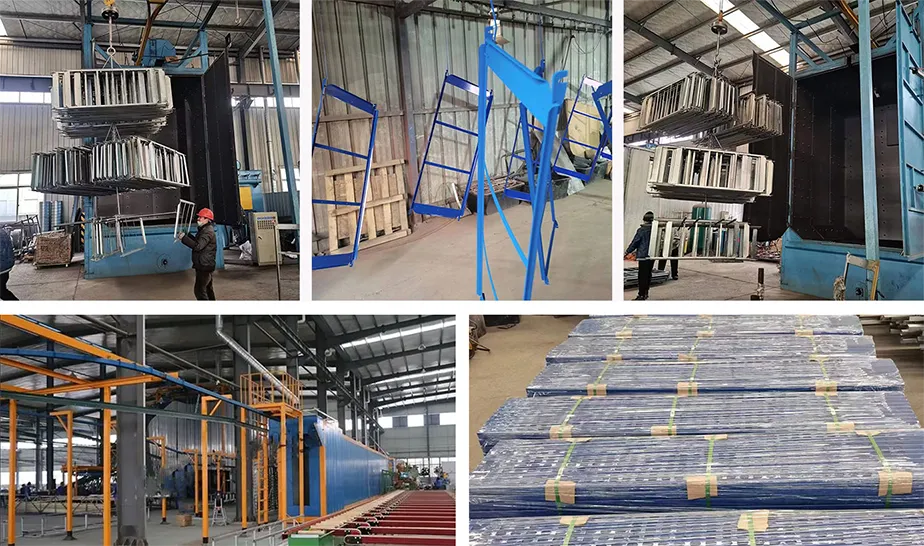

Use automatic electrostatic spraying equipment to evenly apply anti-corrosion powder coating on the metal surface. This layer of coating not only improves the weather resistance of the product, but also enhances the assthetics of the cart.

When the quality inspection of the raw materials is not problematic, we will officially enter the production in stage. The raw materials are first cut, then the parts are stamped and welded, next the surface treatment is done, further polishing and cleaning, and finally the packaging and loading.

Punching equipment line

Robot welding production

Automatic Pressing & Rolling

Powder coating manufacturing line

We use the strictest packaging method to prevent the product from collapsing and causing any injury

During the whole process, we will carry out quality inspection, the experienced quality inspectors will ensure that there are no problems with the goods before they are loaded and delivered