Product Parameter

Application Scenarios

-

Architectural Projects: Custom cladding, ceilings, wall panels, column wraps, decorative screens

-

Industrial Manufacturing: Machine frames, casings, brackets, and enclosures tailored to equipment designs

-

Automotive Fabrication: Customized underbody covers, bulkhead sheets, and interior/exterior panels

-

Electronics & Appliances: Precision-cut housings, back panels, control covers, and component blanks

-

Signage & Branding: Logo-engraved sheets, laser-cut decorative panels, and display frames for retail and commercial use

|

Product characteristics

|

|

name of a part

|

Dutch trolley

|

|

regular size

|

1350*565*1900mm

|

|

Material

|

plywood

|

|

Finish

|

Zinc/hot dip/powder coating

|

|

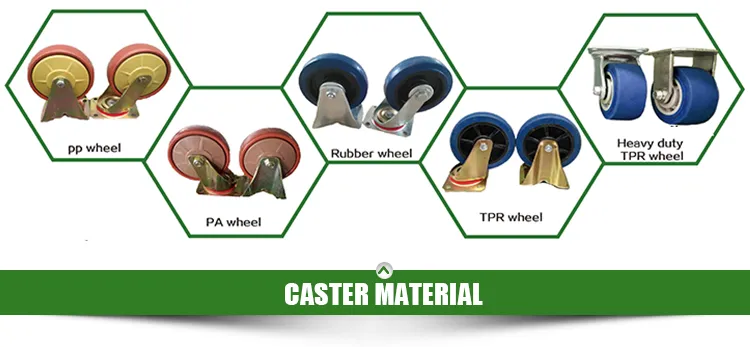

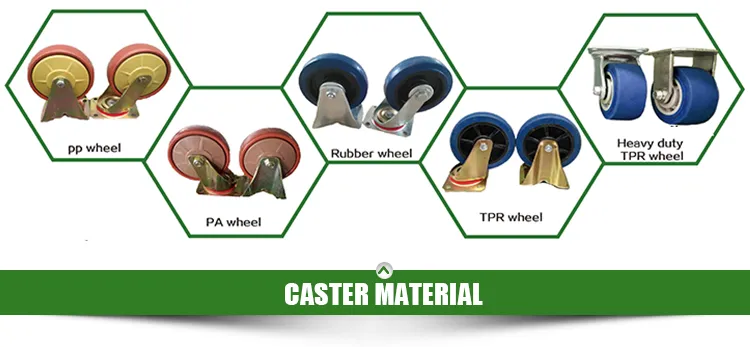

Wheels

|

PP, Nylon, Rubber, PU, TPR wheel

|

|

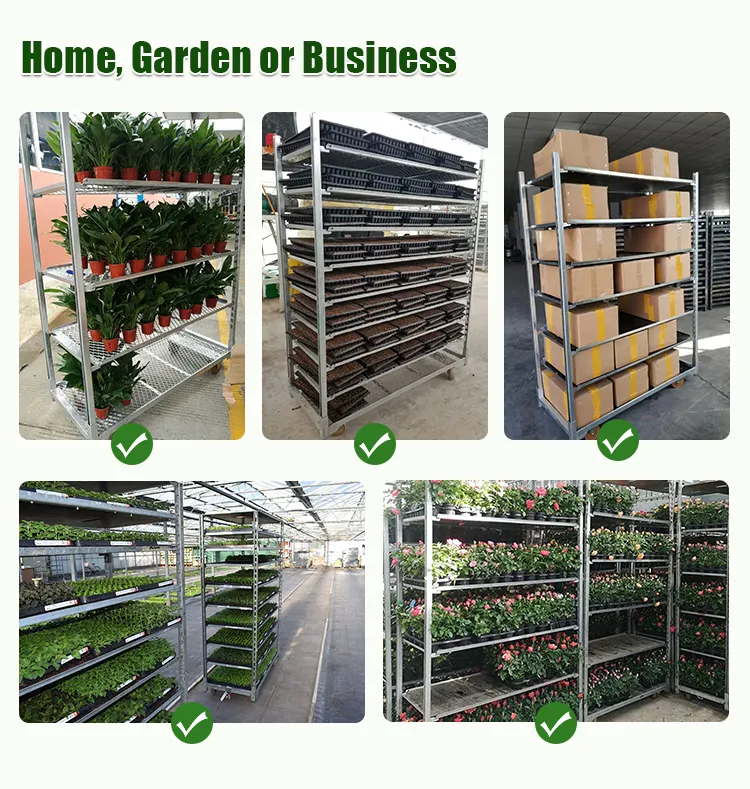

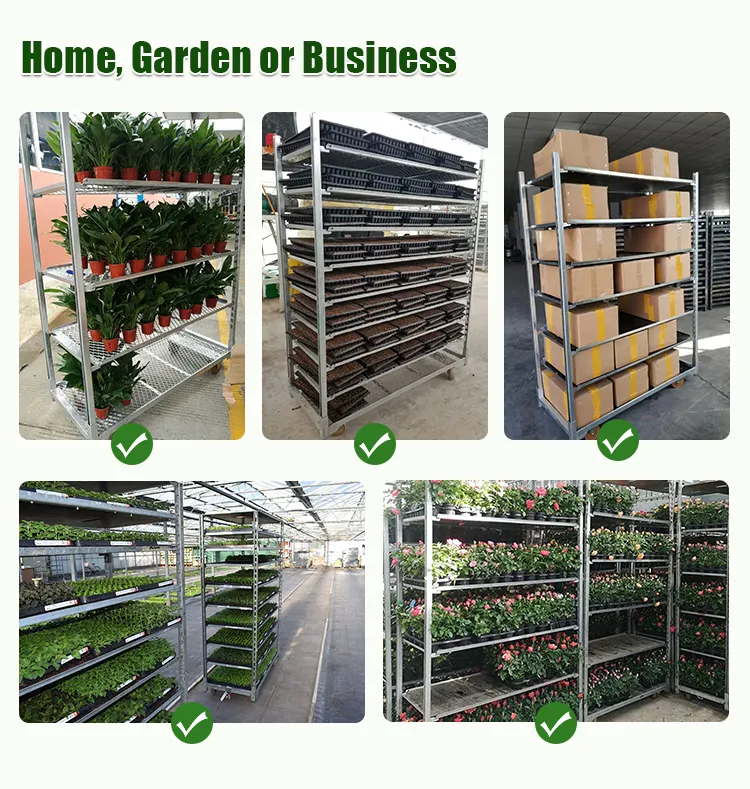

Application

|

Storage, display, logistics transport, plant nursery, garden display

|

|

Product structure

|

Metal sheet, net mesh, plywood, welding mesh/5layers or as your need

|

|

Product Features

|

1. High capacity and stability

|

|

2. Easy to assemble and foldable

|

|

3. The small volume is convenient for transport

|

|

4. Customized is welcomed according to customer’s drawings

|

|

Size(customizable)

|

|

1280*530*1900mm (50.4*20.9*74.8inch)

|

1118*1168*1900mm

(44*46*74.8inch)

|

|

1480*600*1900mm (58.3*23.6*74.8inch)

|

675*565*1900mm

(26.6*22.2*74.8inch)

|

|

1310*1020*1900mm (51.8*40.2*74.8inch)

|

1500*565*1900mm

(44.25*31*83.75inch)

|

|

1330*610*1900mm (52.4*24*74.8inch)

|

1350*565*1900mm

(53.1*22.2*74.8inch)

|

Danish trolley is a kind of unit mobile assembly equipment installed with four casters to transport flower products, which is widely used in flower logistics distribution. Almost all modern flower logistics are using a trolley. By transporting flowers, potted plants or fresh cut flowers are not packed in cartons or wooden boxes, but directly placed on the trolley partition plate, protecting the plant from excessive extrusion and minimizing the loading loss; on the other hand, it also makes the loading and unloading process very labor-saving, which greatly improves the efficiency of loading and unloading vehicles.

Flexible and professional design of the dutch trolley, in the removable side frame, can be installed movable partition, the number of layers and the height of each layer can be adjusted at any time, large space and flexible application. A grille can be placed on the partition to stabilize the pot, which also enables the water transport of fresh cut flowers.

After the product protection plant is on the shelf, it can be attached with the safety belt, or the whole vehicle package for protection, with the label plate, and do the whole delivery together with the trolley itself

The wheels of the humanized design trolley are usually designed for two directional wheels and two universal wheels, in order to facilitate the artificial short-distance implementation in the greenhouse and freight yard, light and flexible transportation

hedanish trolley consists of 1 base(and 4 wheels), 4 posts, and 3 shelf .

The 4 posts have equally spaced holes on them, and the height of the shelves can be adjusted depending on the height of the plants; the number of shelf can be increased or decreased according to your needs. The shelf and shelf can be disassembled when not in use to optimize storage space and reduce the cost of return shipping.The wheels are designed for easy movement, and the material of the wheels can be chosen.Application area: warehouse, logistics, plant and flower industry, propagation room etc.

◆ Flexible and professionally designed flower trolley, movable partition can be installed on the detachable side frame, the number of layers and the height of each layer can be adjusted at any time, big space and flexible application. A grid stable pot can be placed on the partition, which also enables the water transport of fresh cut flowers.

◆ After the product protection plant is put on the shelf, it can be attached with safety belt, or the whole vehicle package for protection, attached with the sign plate, and the cart itself to do the whole transport.

The wheel of humanized design trolley is usually designed for two directional wheels, two universal wheels, in order to facilitate the manual in the greenhouse and goods yard short distance implementation, transport light and flexible.

Advantages

-

Custom Dimensions: Full control over sheet size, thickness, and tolerance to meet precise project requirements

-

Material Variety: Choose from 304/316/430 stainless steel, Q235/Q345 carbon steel, 5052/6061 aluminum, galvanized, and alu-zinc materials

-

Advanced Finishing: Mirror-polish, brushed, frosted, anti-fingerprint, color coating, or laser pattern engraving

-

Fabrication Ready: Sheets can be delivered pre-cut, pre-punched, or folded to reduce your processing time

-

High Precision: ± 0.02 mm tolerance and excellent flatness via advanced rolling, leveling, and CNC calibration systems

Why Choose Us

-

State-of-the-Art Factory: 12,000 m² facility with CNC punching, laser cutting, slitting, shearing, and forming lines

-

Custom Engineering Support: 48-hour CAD drawing review and sampling service for OEM/ODM clients

-

Certified Quality: ISO 9001-certified production with full material traceability and inspection reports (MTC, SGS, CE available)

-

Flexible Order Volume: From small prototyping runs to full container bulk production

-

Global Reach: Exported to 40+ countries with seaworthy packaging, multimodal logistics, and compliance with international standards

-

Reliable After-Sales: Dedicated technical support team, stocked spare inventory, and rapid feedback for repeat buyers

Looking for a Custom Metal Sheet Manufacturer to turn your specifications into high-precision products?

Contact us now to request a quotation, sample, or tailored production plan.